How Much Drilling Sight Ar In The Uk Now

How Much Drilling Sight Ar In The Uk Now - Let the glue set up, check. No gunsmithing, drilling, tapping, or permanent rifle alterations are needed, as the rear sight mounts using existing scope base holes. This was my last project, drilling an ar15 barrel for an old school front sight base. I fully understand that drilling and pinning is the correct, most durable, and accepted way to install an a2 base. The size of the rear aperture depends on factors like the length of the sight plane, the sight range, the level of accuracy desired, and so forth. The job is made 100% easier with the jig i got. Slide the front sight on and adjust by eye or use a square on each side of the sight tower to get properly aligned. These sights are the standard u notch and front post except the rear sights have two green fibre optic dots and the front post is a red fibre.

I fully understand that drilling and pinning is the correct, most durable, and accepted way to install an a2 base. The size of the rear aperture depends on factors like the length of the sight plane, the sight range, the level of accuracy desired, and so forth. Slide the front sight on and adjust by eye or use a square on each side of the sight tower to get properly aligned. No gunsmithing, drilling, tapping, or permanent rifle alterations are needed, as the rear sight mounts using existing scope base holes. The job is made 100% easier with the jig i got. These sights are the standard u notch and front post except the rear sights have two green fibre optic dots and the front post is a red fibre. This was my last project, drilling an ar15 barrel for an old school front sight base. Let the glue set up, check.

Let the glue set up, check. This was my last project, drilling an ar15 barrel for an old school front sight base. These sights are the standard u notch and front post except the rear sights have two green fibre optic dots and the front post is a red fibre. No gunsmithing, drilling, tapping, or permanent rifle alterations are needed, as the rear sight mounts using existing scope base holes. I fully understand that drilling and pinning is the correct, most durable, and accepted way to install an a2 base. The size of the rear aperture depends on factors like the length of the sight plane, the sight range, the level of accuracy desired, and so forth. Slide the front sight on and adjust by eye or use a square on each side of the sight tower to get properly aligned. The job is made 100% easier with the jig i got.

Drilling a Front Sight for Screw Attachment SingleActions

The size of the rear aperture depends on factors like the length of the sight plane, the sight range, the level of accuracy desired, and so forth. The job is made 100% easier with the jig i got. This was my last project, drilling an ar15 barrel for an old school front sight base. These sights are the standard u.

Core Drilling Humpty Doo Diamond Drilling & Mineral Exploration

The size of the rear aperture depends on factors like the length of the sight plane, the sight range, the level of accuracy desired, and so forth. Slide the front sight on and adjust by eye or use a square on each side of the sight tower to get properly aligned. No gunsmithing, drilling, tapping, or permanent rifle alterations are.

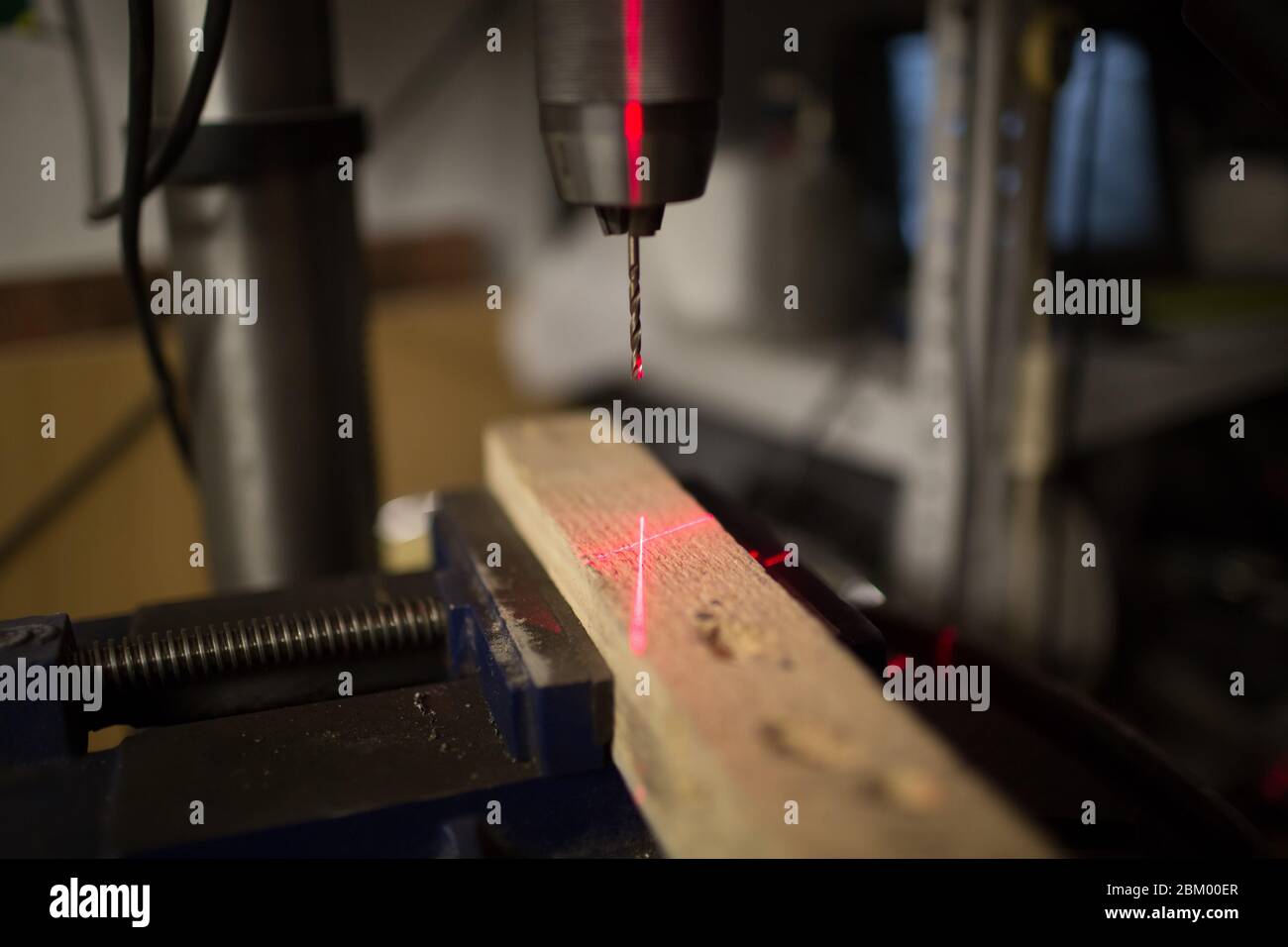

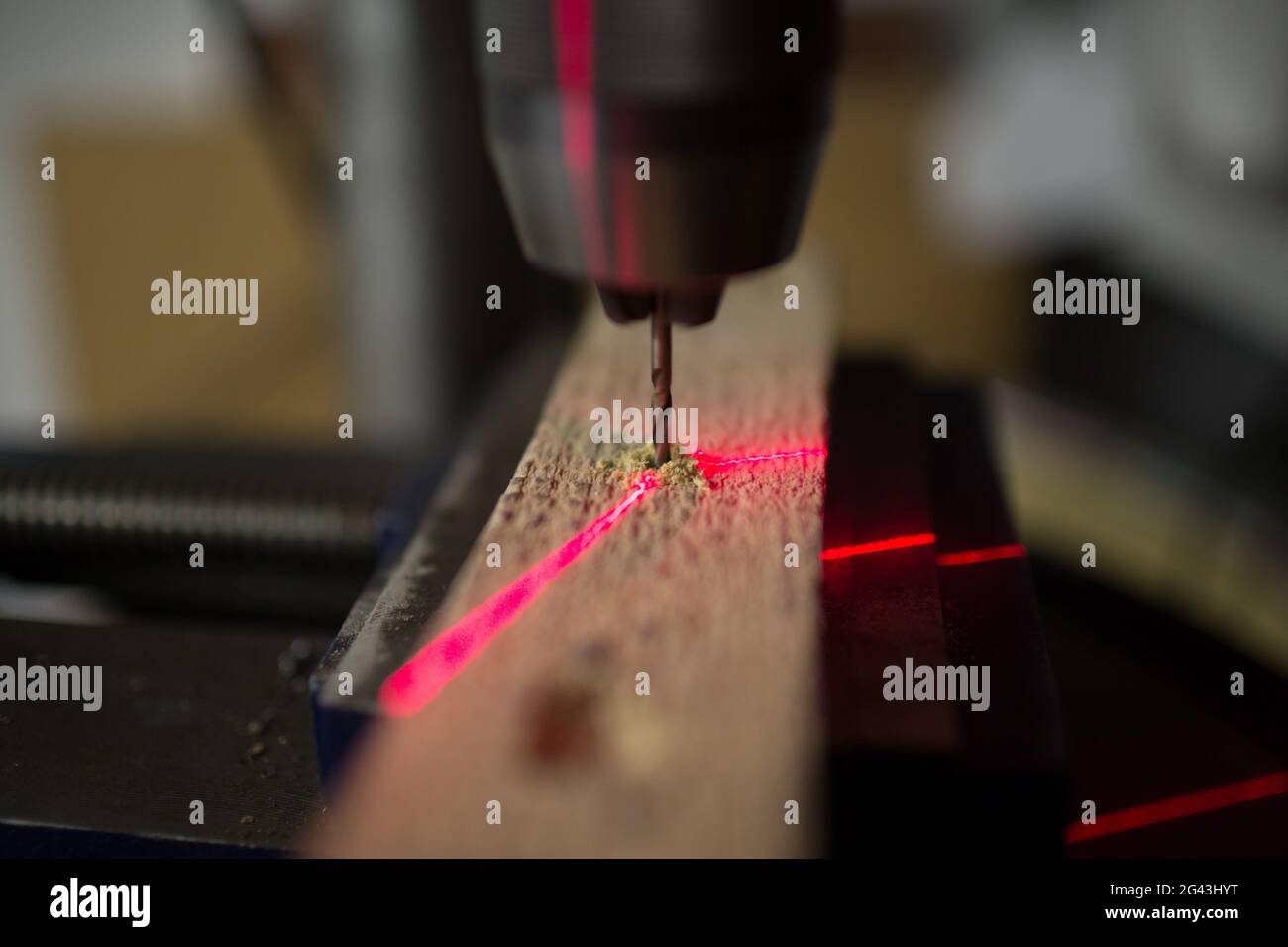

Drilling machine with laser sight in the Stock Photo Alamy

Slide the front sight on and adjust by eye or use a square on each side of the sight tower to get properly aligned. Let the glue set up, check. No gunsmithing, drilling, tapping, or permanent rifle alterations are needed, as the rear sight mounts using existing scope base holes. The job is made 100% easier with the jig i.

Front sight pin drilling jig

No gunsmithing, drilling, tapping, or permanent rifle alterations are needed, as the rear sight mounts using existing scope base holes. This was my last project, drilling an ar15 barrel for an old school front sight base. Slide the front sight on and adjust by eye or use a square on each side of the sight tower to get properly aligned..

Drilling machine with laser sight in the Stock Photo Alamy

Slide the front sight on and adjust by eye or use a square on each side of the sight tower to get properly aligned. Let the glue set up, check. These sights are the standard u notch and front post except the rear sights have two green fibre optic dots and the front post is a red fibre. The size.

Drilling a Front Sight for Screw Attachment SingleActions

This was my last project, drilling an ar15 barrel for an old school front sight base. These sights are the standard u notch and front post except the rear sights have two green fibre optic dots and the front post is a red fibre. The size of the rear aperture depends on factors like the length of the sight plane,.

Drilling machine with laser sight in the Stock Photo Alamy

I fully understand that drilling and pinning is the correct, most durable, and accepted way to install an a2 base. Let the glue set up, check. The size of the rear aperture depends on factors like the length of the sight plane, the sight range, the level of accuracy desired, and so forth. The job is made 100% easier with.

Drilling mud Benefits, Types & Uses Britannica

No gunsmithing, drilling, tapping, or permanent rifle alterations are needed, as the rear sight mounts using existing scope base holes. These sights are the standard u notch and front post except the rear sights have two green fibre optic dots and the front post is a red fibre. The job is made 100% easier with the jig i got. The.

Genseed Underground Services Limited, Directional Drilling specialists

Let the glue set up, check. The size of the rear aperture depends on factors like the length of the sight plane, the sight range, the level of accuracy desired, and so forth. Slide the front sight on and adjust by eye or use a square on each side of the sight tower to get properly aligned. This was my.

Gas Block and Front Sight Base Drilling Jig

I fully understand that drilling and pinning is the correct, most durable, and accepted way to install an a2 base. Let the glue set up, check. These sights are the standard u notch and front post except the rear sights have two green fibre optic dots and the front post is a red fibre. Slide the front sight on and.

The Job Is Made 100% Easier With The Jig I Got.

These sights are the standard u notch and front post except the rear sights have two green fibre optic dots and the front post is a red fibre. Let the glue set up, check. No gunsmithing, drilling, tapping, or permanent rifle alterations are needed, as the rear sight mounts using existing scope base holes. This was my last project, drilling an ar15 barrel for an old school front sight base.

Slide The Front Sight On And Adjust By Eye Or Use A Square On Each Side Of The Sight Tower To Get Properly Aligned.

The size of the rear aperture depends on factors like the length of the sight plane, the sight range, the level of accuracy desired, and so forth. I fully understand that drilling and pinning is the correct, most durable, and accepted way to install an a2 base.